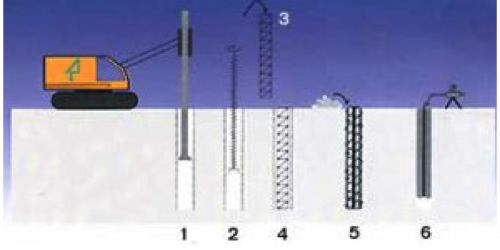

MINI PILE INSTALLATION METHOD

1.0-) SCOPE OF WORK

Mini Piles are installed either as bearing piles under foundations or vertical elements of a retaining wall to prevent vertical displacements and rotational torque of structures.

The installation is initiated in accordance to the pile layout plan and the field surveying which also defines the necessary machinery and equipment.

2.0-) MACHINERY AND EQUIPMENT

- Drilling Rig designed for rotary plus percussive operation

- Rods + Down The Hole Hammer + Consistent Bit

- Continious Flight Auger + Consistent Bit

- Casings and bentonite mixing and pumping set

- Air compressor

- Cement Injection Unit (pump + mixer + agitator

- Water Pump

- Rebar, cutting, bending and stirrup machine

- Generator (If needed)

3.0-) DETAILS OF METHOD OF CONSTRUCTION

3.1-) Drilling

Systems featuring rotary and/or percussive drilling are used in mini piles.

3.1.1-) Rotary Drilling Method

The trust and torque supplied by the machinery are transmitted to the ground via the rods and the consistent bit which depending on soil conditions could be Rock Bit, Pilot Bit, Clay Bit, etc. In clayey soil stratas, augers with clay bits are use. Stratas composed of backfills and aluvial deposits may require temporary casings, drilling fluids during drillings.

3.1.2-) Percussive Drilling Methods

Applied to soil stratas hard and rocky. The torque supplied by the machinery are transferred to the hammer placed at the bottom of the hole. The hammer while rotating, performs a repeated percussive pounding trough its diamond bit. The compressed air operates the hammer while driving the excavated earth and debris outwards from the hole Hole diameter ranges from 225 mm to 300 mm. The methods carried out in order to drive away the excavated earth has a profound effect on drilling pace and drill quality. For this operation air, water and/or drilling foam are used.

3.2-) Placement of Rebar Cage and Cement Injection

The rebar cage contatining the HDPE pipes is placed into the borehole carefully preceding drilling and cleansing. The hole is filled with No.2 pure clean aggregate gradually, excluding any gaps. The borehole is filled with cement injection having w/c ratio ranging in between 0.42 and 0.50 from first injection pipe. Two hours later, the injection process is repeated with the second injection pipe that is piped and punched with a predefined interval. During injection, it is most important that the present water within the hole migrates.

3.3-) As an alternative to the method prescribed in 3.2, readily mixed concrete can be used for injection.

3.4-) Records

- A record card is filled for each pile including;

- Number, place and date of pile

- Pile top and bottom elevations

- Diameter and drilling length of pile

- Start and finish dates for pile

- w/c ratio for the concrete mix that has been injected

- Length of casings

- Soil profile if required.

Copyrights 2014 Altyapı Ltd. Şti. - All Rights Reserved. Produced & Development by Venois Teknoloji