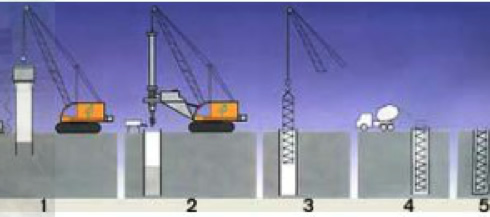

CAST-IN-PLACE BORED PILES CONSTRUCTION METHOD

1.0-) DESCRIPTION

Cast-in-place piles bored are constructed to transfer loads from weak stratas to load bearing stratus or in deep excavations to resist lateral loads. These piles are also known as drilled piles. Type of construction method depends on site and soil characteristic, diameter of pile and depth. Diameter of 50cm to 200cm borehole can be drilled.

Altyapi Foundation Engineering Contracting co. is capable of producing upto 60 meters deep bored piles with its improved machinery & wide experience

2.0-) MACHINERY / EQUIPMENT

- Service Crane

- Rotary Bored Pile Rig

- Kelly - Bar

- Drilling Apparatus & Tools

- Vibratory Hammer

- Casing Ossilators

- Bentonite Tank - Mixer

- Circulation Pumps

- Tremie

- Stirrup, Cutting & Bending Machines

- Electric Generator (If Necessary)

3.0-) DETAILS OF CONSTRUCTION METHODS

ALTYAPI has the capability of choosing different techniques and equipments according to soil conditions and characteristic. Suchas;

3.1-) In soils whichare not stable, liable to flow into borehole, a temporary casing is driven and extracted. Techniques used for driving and extracting are

- Driving & extracting of casing by using vibratory hammer.

- Driving & extracting of double-wall casing by using hydraulic oscillator

- Driving & extracting single / double-wall casing by using hydraulic and rotational pressure

3.2-) In soils that are not stable, instead of casing, bentonite slurry is used.

- Bentonite and water are mixed until adequate density & gel strength forms

- Bentonite slurry must kept min. be 1m level up to ground water level in drilling

- Density of bentonite slurry and sand percentage are checked before concreting. Bentonite slurry is renewed in case there is a problem for concreting by using tremie.

3.3-) Drilling

Borehole is drilled by using rotary drilling machine mounted to crawler crane or hydraulic bored piling rig. Sometimes grabs and chisels used in case soil conditionsdictates.

In soils that are not stable or has high ground water level, casing or bentonite slurry is used. In stable soils, borehole is drilled by using short casing. During drilling, adequate equipment is used for hard soils. Drilling is finished by reaching the depth in the project.

3.4-) Fixing, Installation and Placement of Reinforcement Cage

- Reinforcement cages are installed near by the borehole. The cage is fixed in a riged way to prevent to loosing shape in installation.

- Reinforcement is placed to borehole by using service crane.

- Concrete or plastics spacers are fixed in the bottom and sides of rebar cage to ensure enough spacing.

3.5-) Concreting

- Tremie is placed into bottom of borehole just after placement of reinforcement with service crame

- Segregation of concrete is prevented by using tremie while concreting

- Concrete needs to have a high slump (min 15cm) and to be fluid

- Just Before concreting, tremie is pulled 30cm to 40cm up.

- Tremie must be kept minimum 2m inside concrete in order to prevent mixing concrete and ground water.

- Concreting goes on until sound concrete comes out

3.6-) Quality Control

During and after drilling, depth of the borehole is measured by tape line.

- 4 specimens is taken from each 100m3 concrete and 7 and 28-day-old strength tests results are reported

- Pile loading test is applied if requested.

- Pile integrity testing (PIT) is applied if requested.

3.7-) Records

A record card is filled for each pile including;

- Number, place and date of pile

- Top and bottom level of pile

- Diameter and drilling length of pile

- Start and finish date of drilling

- Amount of concrete used and number of specimens

- Length of casing

- Soil profile if requested.

Copyrights 2014 Altyapı Ltd. Şti. - All Rights Reserved. Produced & Development by Venois Teknoloji